Technical Data ( 技术参数 )

燃料:管道天然气 NG

Fuel:NG

热值: 8500kcal/m3

Calorie Value:8,500kcal/m3

燃气入口压力Inlet: 350mbar to 1000mbar.

Inlet Gas pressure: 350mbar to 1000mbar

烧嘴功率: 630Kw /1500Kw 1:10

Burner Capacity: Max 630Kw/ 1500Kw

炉子工作温度: Max 780℃

Furnace Temperature: Max 780℃

用途: 熔锌合金及热风发生器

Function: Zinc Pot melt and hot air generator

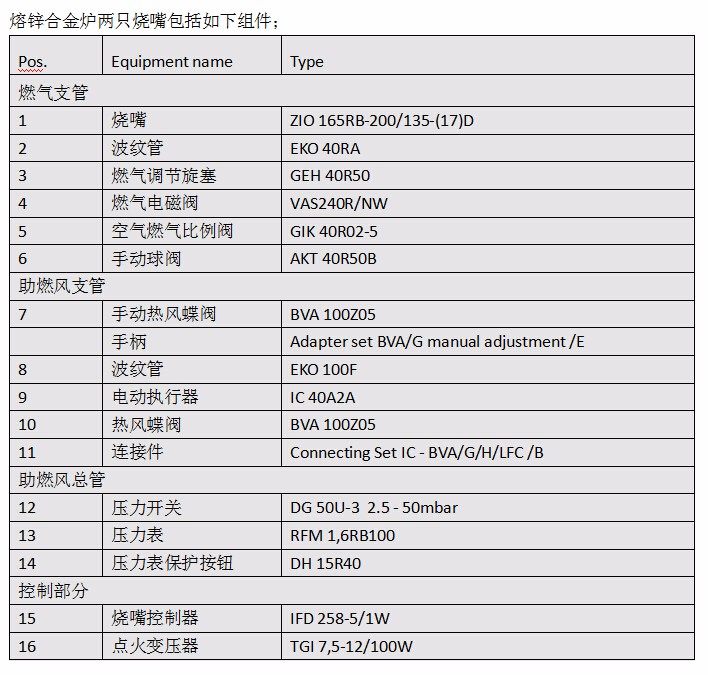

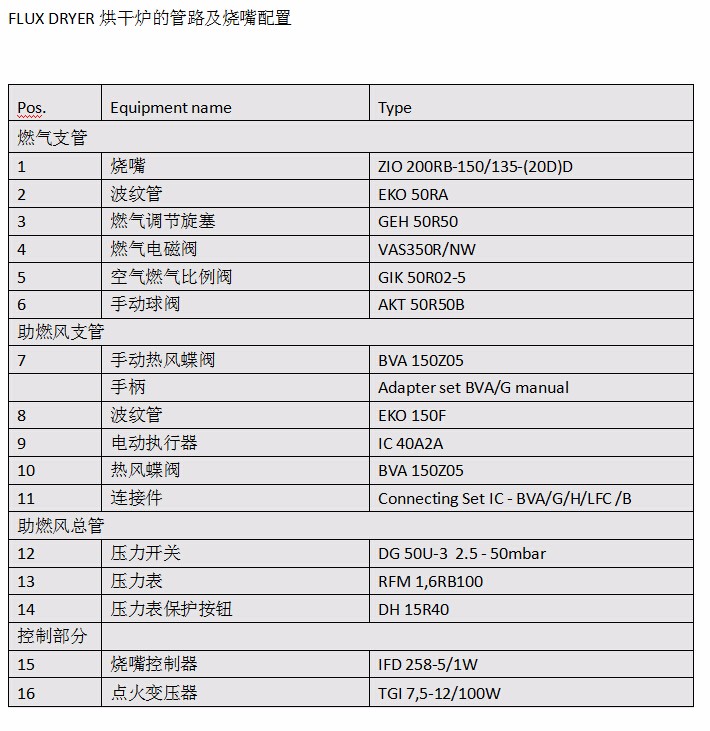

烧嘴数量: 4 支 (630Kw 2pcs; 1500Kw 2pcs) +整体式的燃气机一台套

CONTROL PANEL:

控制柜:

The following control panel will be rack mounted and pre-wired to the gas train:

独立的控制柜被放置在目前的位置,大小与目前相当,内置两套温度记录仪, 并且所有内部接线都安装完毕:

Supply voltage 415/230/1/50Hz

供应电压415/230/1/50Hz

Krom//schroeder Flame Safeguard

Krom//schroeder火焰程序控制器

Krom//schroeder Keyboard/Display Unit, (Flame signal indicator)

Krom//schroeder 输入键盘/显示模块(火焰信号指示)

(1) Krom//schroeder l Self-Check UV Scanner

Krom//schroeder 紫外火焰探测(带自检功能)

VX700R color paperless recorder( VX700R型无纸温度记录仪)

Purge Timer

吹扫延时继电器

Pilot Interrupt Timer

点火点火延时继电器

Power On/Off Switch

电源开关

Burner On/Off push buttons

燃烧器开关按钮

High temperature limit controller with display

高温程序控制器(带数显功能)

(1) Type K Thermocouples

J型热电偶

Ignition transformer and wire

点火变压器及连线

Indicator lights for:

指示灯显示:

Power on(得电)

Interlocks proven(互锁通过)

Purging(吹扫)

Purge complete 吹扫完成(Ready to start准备点火)

Pilot On母火开

Main Burner On燃烧器运行

Flame Failure Alarm火焰熄灭报警

An alarm-fault light reset pushbutton is employed to reset the alarm indicators. An emergency stop push button is also included. These pushbuttons are also door mounted.

带报警指示的复位按钮,用来复位报警。还包括紧急停按钮。这些按钮都安装在控制柜面板上。

PROCESS AIR FAN INCLUDED

工艺风机

AIR Fan with approximately 3000m3/hr and 9000Pa 3 sets

三套供风量为3000立方米/小时,风压为7800-9000Pa的离心式风机;其中:熔锌炉两台烧嘴共用一台风机 ;

Flanged process air inlet and outlet with companion flanges

标准法兰连接的工艺风入口和出口

CONSTRUCTION FEATURES:

组件喷涂事项

All Gas piping painted “Yellow”

所有燃气管路-喷涂黄色

Rack surfaces and components painted “White”

架装表面和组件-白色

Control Panel enclosure “Power Coating RAL 1008”

控制柜喷塑丰田白

Heater Section painted “Silver”

炉体部分-银白色

DOCUMENTATION:

交货文件:

System operation manuals will be provided for the skids, which include:

系统操作手册,包括:

Electrical schematic pre-wire drawing

电路图

Mechanical Drawings

机械组装图

Recommended Spare Parts Lists

推荐备件清单

Component literature

组件表

Pipe train test sheets

管路测试规格表

PRE- TESTING:

试车前测试

The following pre- tests and inspections will be performed at Job side:

以下测试和检验将在现场组装完毕后检测

All pressure switches will be tested for correct operation using Air, regulated to demonstrate trip point, both rising for high-pressure switches and decreasing for low-pressure switches.

所有压力开关出厂前都将使用空气进行打压测试,

All pressure gauges shall be tested for correct readings.

所有压力表都经过打压测试并标定读数

All safety shut off valves will be tested to confirm proper opening and closing sequences.

所有安全切断阀都经过开启和关闭动作测试

All control valves will be tested for full range of motion.

所有控制阀都经过全行程动作测试

All wiring and terminals will be checked for proper routing and continuity.

所有接线和端子都经过严格检查

The entire pipe train will be pressure tested to at least 1.5 times the maximum operating pressure and verified to be leak free.

管路系统经过打压测试,测试压力至少为最大工作压力1.5倍。